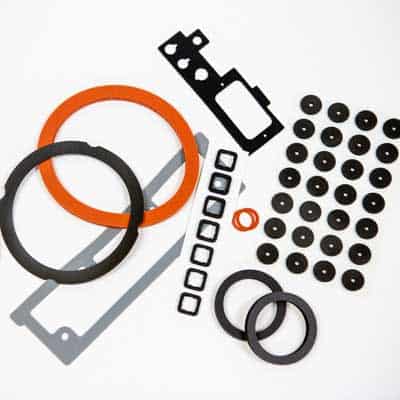

Marian die-cuts custom gaskets and seals using a range of cutting techniques such as rotary die cutting, flatbed die cutting, and laser/waterjet/plotter cutting. The specific manufacturing technique is chosen based on the application, material, and volume. Marian meets and often exceeds dimensional tolerances, even with complex geometries or very small gasket and seal sizes. The finished product is a custom gasket or seal solution specific to your application.

Die-Cut Custom Gasket Features

- Laminated with pressure-sensitive adhesive (PSA)

- Pull-tabs or extended liner

- Kiss-cut to a roll for ease of assembly

- Oriented for automated placement

- Capacity to produce very high volumes

Contact Marian today for information on our precision cut custom gaskets and seals.

Die-Cut Gasket Examples

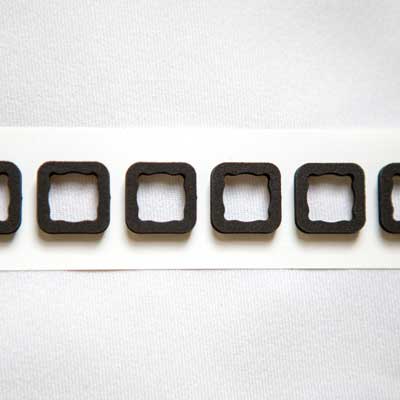

Camera Lens Gasket

This gasket was die-cut, kiss cut to a roll using Rogers PORON® Foam, and laminated on one side with double-coated tape. The PORON® foam offers sealing from water and dust, as well as cushioning from potential impact.

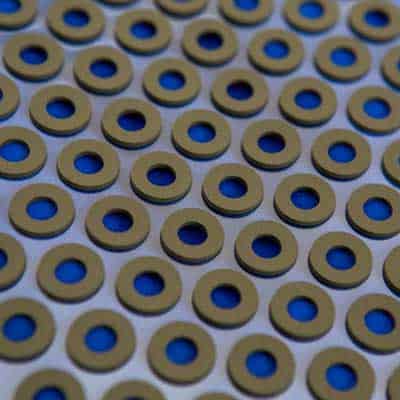

ID/OD Foam Washers

These ID/OD foam washers are manufactured in extremely high volumes. They are made with EPDM foam, and used often for noise reduction, vibration damping, and moisture sealing.

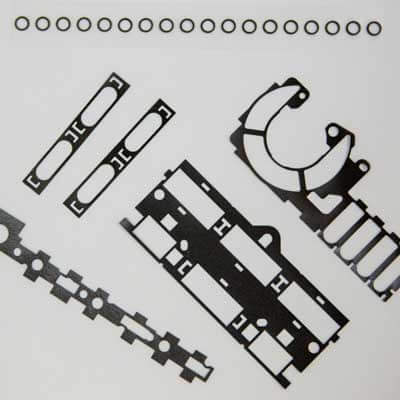

Light Shielding Gaskets

These gaskets offer light blocking and cushioning properties for electronic faceplate displays with an intricate design of buttons and switches. Rogers Poron® Foam material was chosen due to its soft and slow rebound properties.

Gaskets and Seals Prevent Leaks

The purpose of a gasket is to fill the space between two mating surfaces, generally preventing leakage while the material is under compression. Many products and applications require sealing from different elements: air, water, dust, fluid gas, electromagnetic interference, radio frequencies, and light. In addition to preventing leaks and sealing, gaskets can also serve other functions like cushioning, vibration, and noise reduction (washers).

Types of Custom Gaskets

- Environmental sealing gaskets

- Gaskets for for IP Rated enclosures/NEMA rated electrical enclosures

- High temperature gaskets

- ID/OD gaskets (washers)

- Window/LCD screen gasket

- Lens gasket

- Shock/impact protection gaskets

- Cushioning gaskets

- Light sealing tape/gasket

Types of Gasket Material

- Rogers PORON® Polyurethane Foam

- Rogers BISCO® Silicone Foams

- Silicone Rubber Gaskets/Silicone Sponge

- Neoprene Rubber

- EPDM Rubber

- XLPE – Crosslinked Polyethylene

- Acrylic foam tapes

- Gaskets backed with Pressure Sensitive Adhesive (PSA)/Double-coated PSA

- Electrically Conductive Rubber and Foam

- Thermally Conductive Rubber and Foam

Gasket Material Considerations

- Closure force/compression force

- Exposure to certain elements: temperature, weather (outdoors), chemicals, UV

- Product longevity

- Considerations with Specifications/Ratings: IP, NEMA, UL

Related Resources

Success Story: BISCO HT-800 for LED Sealing Gasket

Marian recommends BISCO HT-800 Medium Silicone Foam for a sealing gasket in an outdoor LED Lighting Enclosure. Read more…