Marian manufactures custom die-cut components using pressure sensitive adhesive (PSA) tapes to join two substrates, bonding them together. Marian has established strong relationships with world-class tape and adhesive suppliers. Our solutions using die-cut tapes are ideal for bonding, joining, and assembly of two substrates.

There are many formulations of PSAs designed to obtain a desired level of adhesion to a wide variety of surfaces. However, as the name implies, all PSA products require adequate pressure to be applied to achieve full surface contact.

Be sure to contact us if you have any questions regarding bonding, joining, and assembly of substrates.

Commonly Converted Bonding Materials

- Acrylic foam tapes (3M™ VHB™, tesa® ACXplus.)

- Adhesive Transfer tapes

- Double-coated tapes

- Reclosable fasteners (Dual Lock, Hook and Loop)

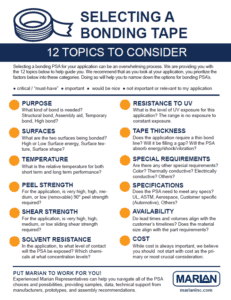

Choosing the right material among these many options can be overwhelming. Experienced Marian representatives can help you navigate all the bonding material choices and possibilities, providing samples, data, technical support from manufacturers, prototypes, and assembly recommendations.

Bonding Tapes – Material Selection Considerations

Examples: Bonding, Joining, and Assembly

Automotive: Emblem, Trim, Molding Attachment

Marian manufactures die-cut attachment solutions that will ensure the automotive emblem, trim, and molding piece will remain securely in place for the life of the product. Double-sided PSA parts can be die-cut with a tab or extended liner for ease of handling and assembly. Read more…

Electronics: Lens/Bezel Attachment

Die-cut 3M™ VHB™ is an excellent material for bonding two low surface energy plastic components, which often join to assemble the housing elements of an electronic device. Marian manufactures die-cut parts with intricate geometries at tight tolerance, often required for electronic devices. Read more…

Medical: Stick-to-skin Device Attachment

Wearables, diagnostics, wound care, and health and beauty are often designed to include an element of bonding to skin with a medical-grade, skin-safe adhesive. Marian has experience in material selection and manufacturing skin-contact components that meet the stringent specifications of the medical market. Read more…

Resources

Success Story: 3M™ VHB™ Permanent Bonding Solution

Marian provided a 3M™ VHB™ part to this beverage vending machine manufacturer that was aesthetically clean and could perform well in extreme conditions. Read more…